+86 28 8393 0607

+86 28 8393 0607

IGBT induction heater power 7-1500KW Frequency 0.1-400Khz For hot forging, induction hardening and tempering, brazing, pipe heating

Power 30-300KW

Work Frequency 50-250Khz

Power 30-300KW

Work Frequency 50-250Khz

30-160KW 10-30Khz Induction Heating Machine

Power 30-250KW

Work frequency 10-30Khz

Low Frequency 250KW Induction Heating System

Power: 250KW

Work Frequency: 0.5-10Khz

500-1500KW Frequency Converter

Power: 350--1500KW

Work Frequency: 0.5-8Khz

DUOLIN has been founded in 1994, now is a professional factory to develop, design and manufacture Induction Heating Equipment. We are cencentrating on the improve of IGBT Induction Heating Technology for 30years, has installed thousands of Induction Heating Process for hot forging, induction hardening, long bar/threaded rod heat-treatment and induction pipe bending, Induction elbow...

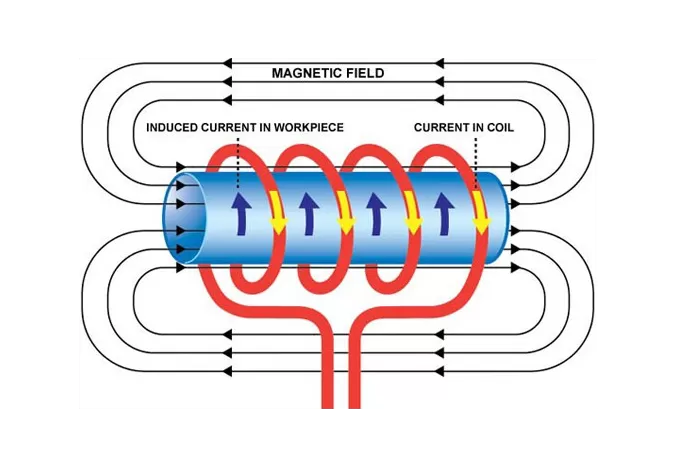

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, through heat generated in the object by eddy currents. An induction heater consists of induction power supply (induction heater) and inductor (coil) that is a shaped to contour the part, and a work station where the part is held and presented to the coil.

Customized Turnkey induction heating machine

Provide solution according to your requirement, well match with your production line

DUOLIN has been founded in 1994, now is a professional factory to develop, design and manufacture Induction Heating Equipment. We are cencentrating on the improve of IGBT Induction Heating Technology for 30years, has installed thousands of Induction Heating Process for hot forging, induction hardening, long bar/threaded rod heat-treatment and induction pipe bending, Induction elbow...

Your team are warmly welcomed to visit our factory and discuss heating requirements for induction heating systems face to face.

14 Feb

Induction Billet Heaters for Forging

In modern forging operations, temperature consistency and production efficiency directly determine part quality and manufacturing cost. Induction billet heaters have become a core heating solution in forging lines due to their speed, precision, and energy efficiency.

27 Feb

Benefits of Induction Billet Heater to Manufacturing Process

Induction Billet Heater—a specialized industrial heating system based on electromagnetic induction—has become an essential tool in pre-heating billets or bars before forging, extrusion, rolling, and other downstream processes.

03 Feb

Copper Blank Induction Heating Machine

customer repeat order for copper heating furnace

15 Jan

1000KW Induction Heater for Hot Pipe Bending Installed in Negria

Induction heating machine for pipe bending

Quick Links

Tel.: +86 28 8393 0607

Mob.: +86 158 8242 2821

WhatsApp: +86 158 8242 2821

Add.: 112th Hancheng Road Xindu Industrial Zone Chengdu China