+86 28 8393 0607

+86 28 8393 0607

Induction Forging Machine

Induction Forging Machine is a specialized piece of equipment designed to rapidly and precisely heat metal workpieces, such as bars, billets, and other forms of metal, to the optimal forging temperature. This process ensures that the metal is malleable enough for shaping under pressure, making it an essential tool in industries requiring high-quality metal parts with enhanced mechanical properties.

Pre-Heating material as the first step is extremely important,compare with conventional gas and coal heating,heating material bar billet with induction has many advantages. Duolin Induction heating machine with latest IGBT technology can raise up the temperature to forging from surface to blank core very quickly and uniform, less oxidation, easy to control heating temperature and time, ensure good quality of hot forging work piece,extend the worktime of die and press.

Match with material handling system and PLC, Duolin induction heating system will offer you high production and stable automatic hot forging production line.

Duolin, founded in 1994, is a trusted manufacturer of induction heating machines and solutions, with over 30 years of industry experience. Offering equipment with power ranges from 4-2000KW and frequencies from 0.5-400KHz, all products are designed by Duolin's expert engineering team and produced under strict ISO9001:2015 standards. As a high-tech enterprise, Duolin holds more than 20 national patents, providing energy-efficient and reliable induction heating systems for industries worldwide.

Duolin's induction heating solutions are widely used for applications such as carbon steel hot forging, gear shaft hardening, long bar heat treatment, pipe heating for hot bending, and non-ferrous metal heating like aluminum and copper. Since expanding internationally in 2007, Duolin has established agents in countries like Brazil, Germany, and India, with end users in over 15 countries, some of whom have been partners since 2009.

Induction billet heating line for total heating

Induction heating equipment with slot inductor for bar end heating

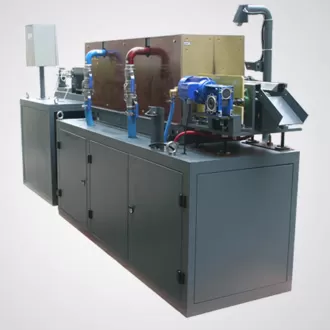

Integrated induction heat line: induction power supply built in with inductor, less space requirement, PLC control.

Duolin offers a wide range of high-quality Billet And Bar Heating Equipment tailored to meet the specific needs of industrial forging applications. Whether you require a Hot Forging Of Steel Billets , Hot Forging Of Carbon Steel or advanced Hot Forging Of Bars, our solutions are designed for efficiency and precision. We specialize in Induction Billet Heating Systems For Forging, which ensures optimal heating performance. Our Induction Heating For Forging technology guarantees consistent and uniform heating, while the Induction Billet Heater models we provide are perfect for high-capacity production lines. Trust our Billet Heating Systems for reliable and cost-effective heating solutions.

Induction billet forging furnace

Power output: 100-1500KW

Frequency: 0.5-10Khz

Bar Diameter: 15-200mm

Output: 0.2-4T/h

Temperature: 800-1250℃

Material: Carbon steel, Brass, Iron, Alloy steel, Stainless steel, Aluminum,Bar, flat plate, bar end heating, flat bar, pipe ends, etc.

Applicatiion: Induction heating for hot forge

Induction heating technology is increasingly being used for industrial forging applications because it offers an unbeatable combination of speed, consistency, control and efficiency.

Duolin offers induction billet heater used for heating a wide range of bar and billet diameters.

Induction power supply is the latest generation; help you benefit from modern forging industry.

No combustible gases

Heating rapidly reduce oxide skin on billet

Improve the working environment

Uniform heating temperature increases die life

Continuously working, 24 hours non-stop

Be Started up 100% at any load

Less interference to others equipment in workshop (Proved by CE)

IGBT inversion technology & LC series circuit design achieve energy saving up to 15%-30% compared with SCR technology

Easy to operate and maintain

Offer PLC to complete fully automatic production line and high heating output

Support conveyors or chain feeding and temperature sorter system

Design coil to match with duolin induction converter ensure max output power

Layout of the complete induction forging unit

What is information we need to know before offer induction heating machine for forging?

1: The heat bar material,carbon steel stainless steel or non ferrous metal

2: Heating billet diameter and heating length

3: Heating production per hour for each dimension

4: Need total heating or just bar end heating

5: Feeding manual or automatic

6: Need infrared thermometer or not

7: Need water cooling system or not

Induction Heating Equipment Model with Heating Production

| MFP-100 | MFP-160 | MFP-200 | MFP-300 | MFP-400 | MFP-600 | MFP-800 | MFP-1200 | Heating Furnace Length |

BJX-120 | 1.25 meter | ||||||||

BJX2-95 | 2 meter | ||||||||

BJX3-95 | 3 meter | ||||||||

BJX4-95 | 4 meter | ||||||||

BJX4-120 | 5 meter | ||||||||

Heating production | 0.2-0.25 | 0.3-0.37 | 0.4-0.5 | 0.7-0.75 | 0.9-1 | 1.4-1.5 | 1.9-2 | 2.9-3 | Ton/Hour |

Diameter range | 25-50 | 25-70 | 30-80 | 40-100 | 40-140 | 40-140 | 50-160 | 60-200

| mm |

Note | For carbon steel to 1200 celcius degree only,if stainless steel,copper,aluminium material,need to recalculate. | ||||||||

|  |  |

| Bar Head Hot Forging For Bolts | 250KW Bar End Heating Oven | Two Station Heating |

|  |  |

| Small Diameter Induction Heating | Long Bar Continuous Heating | Steel Ring Heating |

|  |  |

| Automatic Feeding System For End Forging | Pipe Heating | 90 mm Aluminium Bar Induction Heating System |

|  |  |

| Copper Heating | Tube End Heating | Diameter 150mm Billet Induction Heater |

|  |  |

| Steel Plate Heating | Hexagonal Bar End Heating | Hoe Argriculture Tool Induction Heating |

|  |  |

| Bar Local Heating | Aluminum Heating | 800KW Induction Heating Equipement Work environment |

|  |  |

| Long Bar End Heating | Automatic PLC System for Induction Forging System | Steel Wire Heating |

|  |  |

| 500KW Billet Heater | Bar Total Heating | Square Billet Hot Forging |

Our comprehensive induction forging systems include automated induction forging systems, modular induction forging machines, and multi-station induction forging heaters, designed to streamline your production processes. The smart induction forging equipment integrates advanced technology for precision, while water-cooled and air-cooled induction forging machines provide versatile solutions for various production environments. The integrated induction forging system offers a seamless workflow, and our compact induction forging heaters and mobile induction forging units are perfect for space-saving and mobile applications.

For optimal performance, our closed-loop control induction forging machines and energy-saving induction forging systems ensure efficiency, while rapid heating induction forging technology guarantees faster processing times. We offer induction forging with automatic temperature monitoring, AI-driven process control, and eco-friendly induction forging solutions to meet modern production standards.

Our induction forging solutions are ideal for high-speed production lines, providing high-precision induction heating for forging. Whether you need steel bar induction forging heaters, billet heating induction forging machines, or induction forging for precision parts, our equipment delivers consistent, reliable results. We cater to a wide variety of industries, including induction forging for high-temperature alloy steel parts, axle forging, suspension components, railway parts, and automotive components.

Specialized induction forging for aerospace components, jet engine parts, hand tools, and fasteners ensures the highest standards of quality. We also support industries like wind turbine component forging, hot stamping, and aluminum, copper, and titanium induction forging. Our systems are ideal for precision induction heating for aerospace forging, engine valve production, and bearing raceway forging.

Additionally, we offer modular induction hardening systems, compact induction hardening machines, and mobile induction hardening units. Our vertical and horizontal induction hardening systems, rotary table induction hardening equipment, and inline induction hardening systems are designed for mass production applications. We also provide induction case hardening machines, induction quenching and tempering machines, and multi-coil induction hardening machines to meet a wide range of industrial needs.

Previous: None

Customized Turnkey induction heating machine

Provide solution according to your requirement, well match with your production line

Related Products

IGBT Induction Heating Machine

Good start up performance:IGBT MF induction power supply apply series resonance technology so it can be starts up 100% under any condition.

Induction furnace is critical factor for induction heating process especially for induction hot forge,well designed induction tunnel furnace matching with induction heating power unit will improve the heating efficiency and reduce the oxide scale,therefore,ensure the good quality of hot forging parts.

Solid Sucker Rod Long Bar Two Ends Induction Hot Forge

Sucker rod used to transmit ground power to the oil pump when useing a rod pump to pump oil in oil industry. They are generally solid steel poles made of carbon steel or alloy steel, each about 8 meter long and connected with special couplings. Specially made hollow steel pipes are also used to pump oil which are called hollow oil sucker rods.

Other Application

Explore practical applications of induction hardening machines in automotive, agricultural, and tool manufacturing industries. Learn how induction heating enhances metal part performance.

Hydraulic hot pipe section bending machine is complete tube induction bending equipment for producing hot bends, elbow. Low frequency induction power supply heat the pipe with heating coil to heat pipe from surface to inside reach temperature around 1000 ℃, the hydraulic bending machine will push the pipe and forming different radii and angel hot bends simultaneously.

Induction Soldering & Welding Machine

Induction brazing is a process in which two or more materials are joined together with a filler metal by induction heating. Induction brazing is suitable for many metallic materials, with magnetic materials being heated more readily.

Long Bar Heat Treatment Machine

Induction continuous heat treatment equipment for long bar heat treatment is a high-tech technology developed by applying induction heating technology.

Induction annealing is a kind of heat treatment by induction heater, heat stainless steel or copper to a specified temperature and then cooling at a rate that will produce a refined microstructure.

Quick Links

Tel.: +86 28 8393 0607

Mob.: +86 158 8242 2821

WhatsApp: +86 158 8242 2821

Add.: 112th Hancheng Road Xindu Industrial Zone Chengdu China