+86 28 8393 0607

+86 28 8393 0607

Induction Hardening Machine

Induction hardening process with induction heating is one method to increase the hardness of material surface. Duolin induction quenching equipment will heat up the workpiece surface rapidly to high temperature with high frequency(1-400Khz) induction power supply, cool down fast with cooling medium such as water and oil or other hardening liquid. The case hardening depth will decide the induction heating machine power and work frequency, high frequency induction power supply needed if customer need shallow case depth. If client required deeper depth, low frequency or medium frequency quenching induction power unit needed.

Induction Hardening Machine is a specialized piece of equipment used to surface-harden metal parts, enhancing their durability, wear resistance, and fatigue strength. This process involves rapidly heating the surface layer of the material using induction technology, followed by immediate quenching to create a hard, wear-resistant outer shell while maintaining a tough, ductile core.

Some parts will need induction tempering process to accomplish the induction heat treatment application depending on the requirements. Duolin engineer team can work out complete induction scan heating system. Duolin Induction heat treating furnace is also widely used for the surface or inner hardening of steel. With robot and CNC program induction scanner, Duolin can offer customer whole full automatically induction hardening and tempering production line, like rotate, lift, transfer. Duolin engineer teams have experience in variety of industries, such as oil&gas, aerospace, automotive and so on. Meanwhile, we also supply induction hardening equipment to heat treatment factory.

Duolin, founded in 1994, is a trusted manufacturer of induction heating machines and solutions, with over 20 years of industry experience. Offering equipment with power ranges from 4-2000KW and frequencies from 0.5-400KHz, all products are designed by Duolin's expert engineering team and produced under strict ISO9001:2015 standards. As a high-tech enterprise, Duolin holds more than 20 national patents, providing energy-efficient and reliable induction heating systems for industries worldwide.

Duolin's induction heating solutions are widely used for applications such as carbon steel hot forging, gear shaft hardening, long bar heat treatment, pipe heating for hot bending, and non-ferrous metal heating like aluminum and copper. Since expanding internationally in 2007, Duolin has established agents in countries like Brazil, Germany, and India, with end users in over 15 countries, some of whom have been partners since 2009.

Induction hardening application can be done in two different ways: single shot and scan hardening

Advantages of Induction hardening:

• No physical contact hardening

• Scan/ Stationary hardening

• Short time (a few seconds) hardening increase production and improve quality

• CNC or PLC Control heating and cooling during hardening

Duolin Induction heating equipments for quenching provide induction hardening solution for shaft, gear, roller, steel plate, pin, pipe etc. The frequency of induction heating machines is from 1 KHz to 400KHz, which work with CNC or PLC quenching machines.

Power: 4-1500KW

Frequency: 0.5-400KHz

Hardening Depth: 0.5-10mm

Mechanical Fixture: CNC or PLC Control

Application: Gear, shaft, pipe, bearing, pump fitting, steel plate, roller,wheel,bars

• Precise and fast heating for work pieces

• Reliability, consistency

• Constant power or constant voltage control mode

• Continuously working, 24 hours non-stop

• Less interference to others equipment in workshop (Proved by CE)

• IGBT inversion technology &LC series circuit design achieve energy saving up to 15%-30% compared with SCR technology

• Easy to operate and maintain

• Installation can be one very easily according our manual

Feature

1: The main benefit of induction heating for hardening is fast only takes few seconds

2: Induction verticcal or horizontal hardening machine can be support

3: Can queching wide range of mechanical parts,such as shafts,gears,rollers,pipes,pump fitting,bearing,excavator teeth etc

4: Duolin provides you customized induction hardening solution for your particular job,maximized your benefits

5: Hardening test laboratory to check the hardening depth and hardness

6: CNC control to stock the induction hardening process for different heating job

7: Very friendly to new invester, one induction hardening system can cover many kinds of heating parts

8: Induction hardening and tempering can be finished on same heating equipment

Induction hardening machines are ideal for localized surface treatment of metal parts, especially those subjected to repetitive motion, heavy loads, or extreme friction. Common applications include:Gears/Shafts/Axles/Bearings/Rollers/Tools

Automotive Industry: Induction hardening is widely used in automotive parts that demand high surface hardness and structural strength. Key components include:Crankshafts/Camshafts/Drive shafts/Gear teeth/Steering knuckles/Transmission parts

These parts benefit from faster processing times, controlled hardening depth, and minimal deformation, resulting in better fuel efficiency and longer vehicle life.

Agricultural Machinery: Heavy-duty agricultural tools require high wear resistance due to continuous exposure to soil and impact. Induction hardening is applied to:Plowshares/Harrow teeth/Blades/Coupling components

The hardened surface increases productivity and reduces maintenance costs for farming equipment.

Tool and Hardware Manufacturing: Induction hardening enhances tool life and performance. Common applications include:Wrenches/Screwdriver tips/Hammers/Pliers/Cutters

By selectively hardening tool edges, manufacturers can balance durability and toughness.

Industrial Machinery Components: In industrial automation and machine manufacturing, components like guide rails, rollers, and sprockets are induction hardened to ensure consistent performance under continuous operation.

| Case depth [mm] | Bar diameter [mm] | Frequency [kHz] | Model |

| 0.8 to 1.5 | 5 to 25 | 200 to 400 | HGP30 HGP50 HGP100 HGP300 |

| 1.5 to 3.0 | 10 to 50 | 10 to 100 | Ultrasonic frequency series (10-30KH) |

| >50 | 3 to 10 | Medium Frequency series (1-8KHz) | |

| 3.0 to 10.0 | 20 to 50 | 3 to 10 | Ultrasonic/ Medium frequency series (10-30KH) |

| 50 to 100 | 1 to 3 | Medium Frequency series (1-8KHz) | |

| >100 | 1 | 1 Medium Frequency series (1-8KHz) |

|  |  |

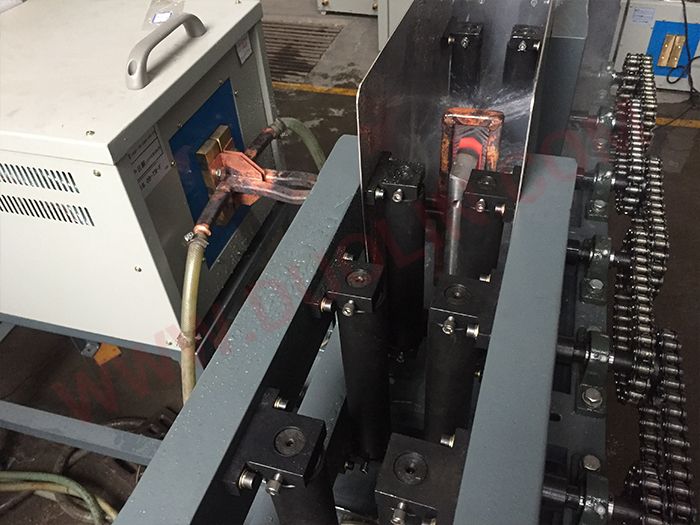

| Agriculture Tool Hardening | Alex Shaft Induction Hardening | Auto Part Induction Hardening |

|  |  |

| Hollow Bar Material Hardening | Shaft Hardening | Steering Knuckle Induction Hardening |

|  |  |

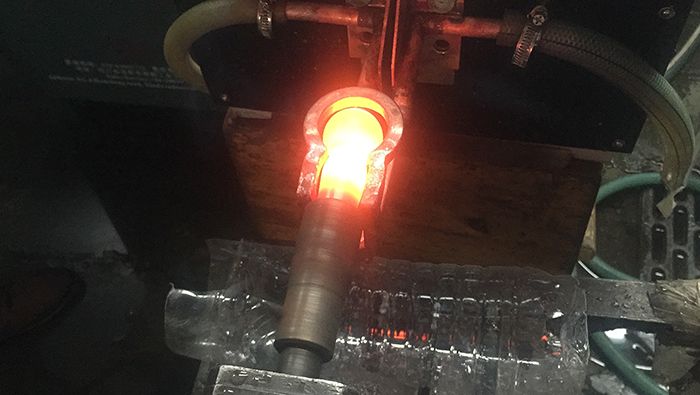

| Ball Pin Induction Hardening | Belt Gear Hardening | Brake Pads Induction Hardening |

|  |  |

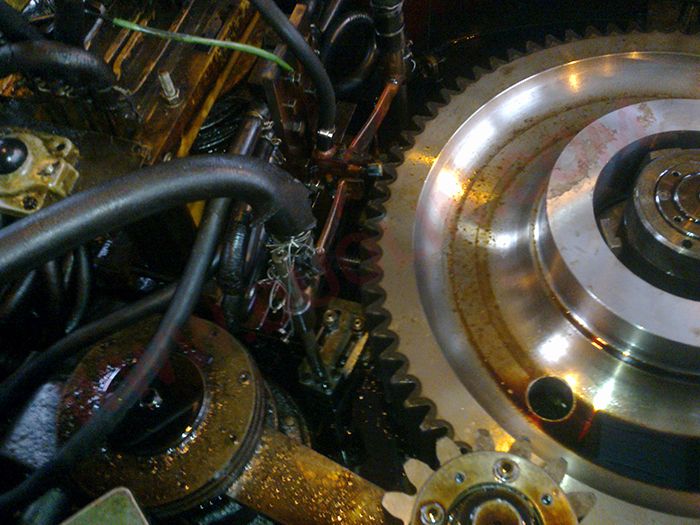

| Sissor Induction Hardening | Clutch Induction Hardening | Two Spindle Induction Hardening |

|  |  |

| Steel Plate Induction Hardening | Shaft Hardening Installation | Wheel Induction Hardening |

|  |  |

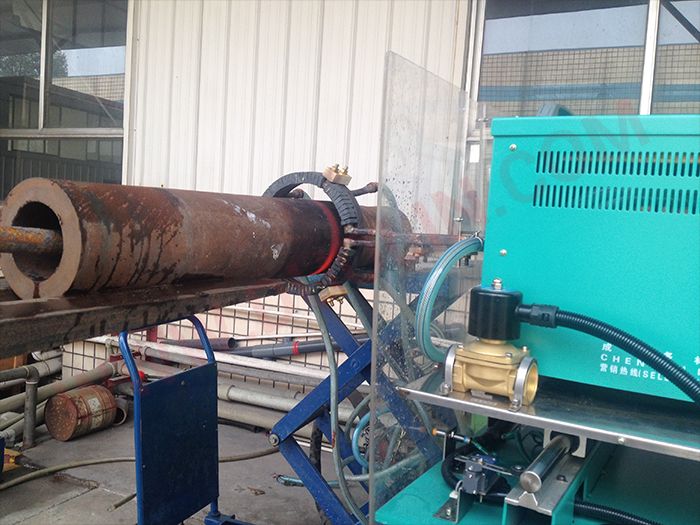

| Roller Induction Hardening | Horizontal Induction Hardening | Pipe Inner Diameter Surface Hardening |

|  |  |

| Gear Hardening | Single Teeth Induction Hardening | Gear Induction Hardening |

|  |  |

| Single Teeth Oil Quenching | Shaft Induction Hardening | Pump Fitting Induction Hardening |

Feature

1: The main benefit of induction heating for hardening is fast only takes few seconds

2: Induction verticcal or horizontal hardening machine can be support

3: Can queching wide range of mechanical parts,such as shafts,gears,rollers,pipes,pump fitting,bearing,excavator teeth etc

4: Duolin provides you customized induction hardening solution for your particular job,maximized your benefits

5: Hardening test laboratory to check the hardening depth and hardness

6: CNC control to stock the induction hardening process for different heating job

7: Very friendly to new invester, one induction hardening system can cover many kinds of heating parts

8: Induction hardening and tempering can be finished on same heating equipment

Hardening requirement we need to know to offer hot quenching solution

1: The drawing of hardening parts

2: Material and hardening position

3: The hardness and hardening depth required

4: Require hardening production or not

Our induction hardening solutions are designed for a wide range of applications, including induction hardening for crankshaft production, gearbox components, engine valve seats, suspension components, and railway axle shafts. We also provide induction hardening for transmission gears, turbine blades, aircraft landing gear, marine engine parts, cutting tools, and drill bits and chisels. Our systems are also ideal for spanners and wrenches, bearing raceways, hydraulic cylinder rods, machine tool guideways, and excavator pins and bushings.

For mining applications, we offer induction hardening for mining drill rods, wear-resistant steel plates, and heavy-duty gears. We specialize in CNC-controlled induction hardening machines, high-frequency induction hardening systems, and medium-frequency induction hardening equipment to meet various industry demands. Our solid-state induction hardening furnaces, portable induction hardening machines, and heavy-duty induction hardening systems provide versatile options for both small-scale and large-scale operations.

Our smart induction hardening machines, multi-station induction hardening systems, and dual-frequency induction hardening heaters offer advanced solutions for precise, automated processes. Additionally, our automated induction hardening production lines and high-power induction hardening machines ensure maximum efficiency and throughput. We also offer induction surface hardening equipment for applications requiring localized surface treatment.

Previous: Induction Forging Machine

Customized Turnkey induction heating machine

Provide solution according to your requirement, well match with your production line

Related Products

100-300KW High Frequency Induction Heating Equipment

Power 30-300KW

Work Frequency 50-250Khz

The induction heating and quenching machine tool is one of Duolin complete sets of induction hardening equipment. The Vertical or horizontal machine tool is mainly used to process shafts parts, gear, bar and also can quenching some special workpieces.

The function of transformer in induction heating is to achieve electromagnatic inductin heating through the transformer action.

Other Application

induction hot forging process is refered to heat the metal part to forging temperature and then the metal was shaped by hammer、press or friction screw press with die or not. the metal can be ferrous like carbon steel、alloy steel、stainless steel or non-ferrous like copper、aluminium and brass, which is widely application like automotive, farm machinery, oil and gas, nuclear defense industry.

Hydraulic hot pipe section bending machine is complete tube induction bending equipment for producing hot bends, elbow. Low frequency induction power supply heat the pipe with heating coil to heat pipe from surface to inside reach temperature around 1000 ℃, the hydraulic bending machine will push the pipe and forming different radii and angel hot bends simultaneously.

Induction Soldering & Welding Machine

Induction brazing is a process in which two or more materials are joined together with a filler metal by induction heating. Induction brazing is suitable for many metallic materials, with magnetic materials being heated more readily.

Long Bar Heat Treatment Machine

Induction continuous heat treatment equipment for long bar heat treatment is a high-tech technology developed by applying induction heating technology.

Induction annealing is a kind of heat treatment by induction heater, heat stainless steel or copper to a specified temperature and then cooling at a rate that will produce a refined microstructure.

Quick Links

Tel.: +86 28 8393 0607

Mob.: +86 158 8242 2821

WhatsApp: +86 158 8242 2821

Add.: 112th Hancheng Road Xindu Industrial Zone Chengdu China