+86 28 8393 0607

+86 28 8393 0607

May. 08, 2025

Induction hardening is a heat treatment method used to selectively and rapidly harden the surface of a metal. In this process, a copper coil carrying an alternating current is positioned near—without touching—the metal part. The alternating magnetic field induces eddy currents and hysteresis losses, generating heat at the surface. The heated area is then rapidly cooled using a water-based quench, often enhanced with polymers, transforming the structure into martensite—a much harder phase than the original.

Induction hardening offers several key advantages:

Enhanced strength and fatigue life: The combination of a hardened surface and a softer core, along with the development of residual compressive stresses, leads to improved overall strength and extended fatigue life. This is due to the expansion of the surface structure as it transforms into a harder phase.

Customizable hardness through tempering: Components can be tempered after hardening to adjust the final hardness level. Greater tempering reduces both hardness and brittleness, allowing for tailored mechanical properties.

Minimal distortion: Compared to other hardening methods, induction hardening causes significantly less distortion or warping, making it ideal for precision components.

Cost efficiency: This process allows for the use of lower-cost steels, reducing overall material and processing expenses while still achieving high-performance results.

Improved wear resistance: When applied to annealed or pre-softened materials, induction hardening dramatically enhances surface wear resistance, extending component lifespan in demanding applications.

While induction hardening offers many advantages, it also comes with certain limitations:

Distortion: The rapid heating and quenching, along with the martensitic transformation, can lead to higher levels of distortion compared to processes like ion or gas nitriding. However, this distortion is generally still less than that produced by conventional heat treatments.

Risk of cracking: The intense thermal gradients and stress introduced during the process increase the potential for cracking, especially in complex geometries or high-carbon steels.

Material restrictions: Induction hardening is not suitable for all materials. It is most effective on steels with sufficient carbon content, making it less versatile than some other surface hardening techniques.

Induction hardening excels in high‑volume production of automotive and industrial components—camshafts, crankshafts, gears, axles, and bearings—where performance gains justify the upfront investment. When evaluating, consider part complexity, batch size, material grade, desired case depth, and permissible distortion. For small batches or complex geometries, flame or furnace methods may be more cost‑effective despite longer cycle times.

Induction hardening delivers swift, precise, and energy‑efficient case hardening that significantly boosts component durability, wear resistance, and fatigue life. However, high initial capital, specialized tooling, limited material scope, and potential cracking or distortion necessitate careful application. Manufacturers should balance these pros and cons against production volume, material selection, and part geometry to choose the optimal hardening method.

If you’re seeking a reliable induction hardening supplier with turnkey capability and technical support, contact us to discuss your specific requirements and sample trials.

Latest News

Welcome India Customer to Duolin Accept the 2 Production Line of Long Bar Heat treatment

Jan. 26, 2026

1000KW Induction Heater for Hot Pipe Bending Installed in Negria

Jan. 15, 2026

Induction heating machine for pipe bending

Case Presentation

Customized Turnkey induction heating machine

Provide solution according to your requirement, well match with your production line

Related Products

The function of transformer in induction heating is to achieve electromagnatic inductin heating through the transformer action.

Reform the Manual Production Line to Automatic

Under background of industry 4.0 and customer new request for saving the labor,full and semi-automatic production become the new trends in manufacturing industry.

Solid Sucker Rod Long Bar Two Ends Induction Hot Forge

Sucker rod used to transmit ground power to the oil pump when useing a rod pump to pump oil in oil industry. They are generally solid steel poles made of carbon steel or alloy steel, each about 8 meter long and connected with special couplings. Specially made hollow steel pipes are also used to pump oil which are called hollow oil sucker rods.

Automatic Induction Brazing for Wear-resistant Plate

The pump truck spectacle plate is a plate that looks like glasses, also known as a wear-resistant plate. It is often used in concrete pumps in the industrial field.

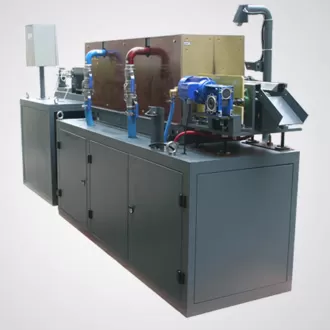

The induction heating and quenching machine tool is one of Duolin complete sets of induction hardening equipment. The Vertical or horizontal machine tool is mainly used to process shafts parts, gear, bar and also can quenching some special workpieces.

Induction furnace is critical factor for induction heating process especially for induction hot forge,well designed induction tunnel furnace matching with induction heating power unit will improve the heating efficiency and reduce the oxide scale,therefore,ensure the good quality of hot forging parts.

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, through heat generated in the object by eddy currents. An induction heater consists of induction power supply (induction heater) and inductor (coil) that is a shaped to contour the part, and a work station where the part is held and presented to the coil.

Quick Links

Tel.: +86 28 8393 0607

Mob.: +86 158 8242 2821

WhatsApp: +86 158 8242 2821

Add.: 112th Hancheng Road Xindu Industrial Zone Chengdu China