+86 28 8393 0607

+86 28 8393 0607

Nov. 12, 2025

In modern manufacturing, metal components such as shafts, gears, sleeves, and rollers often require exceptional surface wear resistance, fatigue life, and dimensional accuracy. Induction hardening has become a preferred heat treatment method for these precision parts. Leveraging Duolin’s advanced induction hardening machines, this article explores how these machines deliver both precision and performance in industrial applications.

Induction hardening is a process that uses electromagnetic induction to rapidly heat the surface of a metal part, followed by immediate quenching. This transforms the surface into a hard, wear-resistant layer while keeping the core softer and tougher.

The process involves passing high-frequency or medium-frequency current through a copper coil to generate an alternating magnetic field. When a metal part is placed inside or near the coil, eddy currents heat the surface rapidly to the hardening temperature (typically 800–950 °C), then a quenching medium cools it quickly, forming a martensitic structure.

This surface-hardening-with-core-toughness approach ensures components are both durable and resilient — ideal for high-load mechanical parts.

Compared to traditional furnace quenching or flame hardening, Duolin’s induction hardening machines offer multiple advantages:

Precision and controlled hardening: Only the required surface area is heated, avoiding distortion or heat damage to the core.

Enhanced wear resistance and fatigue life: Martensitic surface layers and residual compressive stresses improve durability and longevity.

High efficiency and energy savings: Rapid local heating and quenching, combined with CNC automation, drastically reduce processing time per part.

Consistency and repeatability: Pre-programmed parameters (heating time, cooling time, rotation speed, position, etc.) ensure uniform quality across high-volume production.

Reduced distortion and rework: Minimal overall heat reduces warping compared to full-part quenching.

Induction hardening is particularly suitable for long shafts, rods, gears, and parts where only specific areas need hardening, offering flexibility traditional methods cannot match.

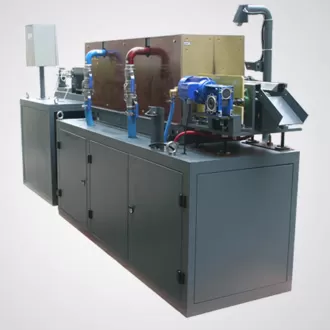

Duolin’s machines are designed to meet the demands of modern industrial production:

Vertical or horizontal configurations: Handle different shapes, lengths, and weights of parts.

CNC control with servo motors: Store and recall multiple hardening programs for quick changeover between part types.

Rotating spindle with variable frequency and quench spray: Ensures uniform heating and cooling to prevent uneven hardening.

Linear guides and servo-controlled transformer movement: Precise coil positioning with repeatability up to 0.01 mm.

Versatile applications: Can also be used for preheating, tempering, or other thermal processes.

These features make Duolin induction hardening machines an efficient, reliable, and flexible solution for industrial heat treatment.

Induction hardening machines are widely used in:

Automotive components: Shafts, camshafts, crankshafts, gears, splines — where surface hardness, wear resistance, and fatigue life are critical.

Industrial machinery, agricultural, and mining equipment: Bearings, rollers, and sleeves exposed to high wear.

Heavy-duty and long or complex parts: Traditional furnace hardening may be impractical; induction provides flexibility.

High-stress applications: Conveyors, presses, and drive systems requiring durable, wear-resistant surfaces.

Essentially, any part needing “hard surface + tough core + precise dimensions + high repeatability” benefits from induction hardening.

While induction hardening offers many benefits, it’s not suitable for all situations:

Material limitations: Best for medium-carbon or alloy steels; low-carbon steels may not harden effectively.

Complex geometries: Sharp transitions, holes, or slots can cause uneven heating or cracking, requiring specialized coil design.

Initial investment: Higher upfront cost than flame or furnace quenching, making it ideal for medium to high-volume production.

Precise process control required: Heating time, frequency, cooling rate, and spindle rotation must be carefully managed.

Induction hardening machines, particularly modern CNC-controlled systems like Duolin’s, provide an efficient, precise, and repeatable solution for metal component heat treatment. They enhance wear resistance, fatigue life, and overall quality, while enabling high production efficiency.

For parts demanding high precision, high durability, and consistent performance, induction hardening is a highly competitive heat treatment method — combining both technological sophistication and industrial practicality.

Latest News

1000KW Induction Heater for Hot Pipe Bending Installed in Negria

Jan. 15, 2026

Induction heating machine for pipe bending

Induction Billet Heater: Precision Heating for Modern Metalworking

Jan. 12, 2026

In the fast-paced world of metal processing, precision, efficiency, and reliability are key. Induction billet heaters have emerged as a vital solution for preheating metal billets before forging, extrusion, or rolling.

Case Presentation

Customized Turnkey induction heating machine

Provide solution according to your requirement, well match with your production line

Related Products

The induction heating and quenching machine tool is one of Duolin complete sets of induction hardening equipment. The Vertical or horizontal machine tool is mainly used to process shafts parts, gear, bar and also can quenching some special workpieces.

Induction furnace is critical factor for induction heating process especially for induction hot forge,well designed induction tunnel furnace matching with induction heating power unit will improve the heating efficiency and reduce the oxide scale,therefore,ensure the good quality of hot forging parts.

In 2018, we received bid for BYD auto for induction pipe bending project, they want to expand their steel structure factory for hot pipe&tube bender industry, to get new increasing profit because the order for auto industry decrease recent year.

DUOLIN Induction hardening is the most common form of induction heat treatment. It is widely used on shaft, gear, pipe .pin and other part in automotive industry.

Vehicle Parts Connection Rod Hot Forging

Induction hot forging is the most common heating application for induction heating,end hot forging for fasteners manufacture,complete billet heating for hot stamping in vehicle parts industry etc

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, through heat generated in the object by eddy currents. An induction heater consists of induction power supply (induction heater) and inductor (coil) that is a shaped to contour the part, and a work station where the part is held and presented to the coil.

Quick Links

Tel.: +86 28 8393 0607

Mob.: +86 158 8242 2821

WhatsApp: +86 158 8242 2821

Add.: 112th Hancheng Road Xindu Industrial Zone Chengdu China