+86 28 8393 0607

+86 28 8393 0607

Jun. 16, 2017

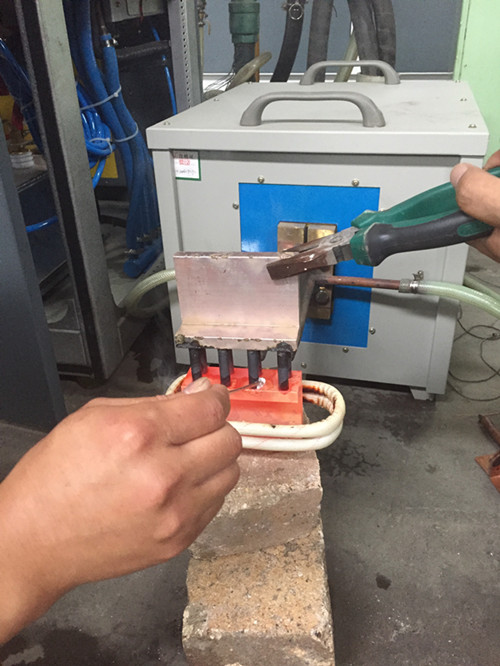

Copper tube induction brazing/welding

There are specific reasons to use induction heating for industrial brazing/welding. These include selective heating, better joint quality, reduced oxidation and acid cleaning, faster heating cycles, more consistent results and suitability for large volume production.

It can be used for oil and gas industry, medicine industry for sealing, copper tube welding etc.

Induction brazing is a very repeatable process because variables such as time, temperature, alloy, fixturing, and part positioning are very controllable. The internal power supply of the RF power supply can be used to control cycle time, and temperature control can be accomplished with pyrometers, visual temperature sensors or thermocouples

Latest News

Copper Blank Induction Heating Machine

Feb. 03, 2026

customer repeat order for copper heating furnace

1000KW Induction Heater for Hot Pipe Bending Installed in Negria

Jan. 15, 2026

Induction heating machine for pipe bending

Case Presentation

Customized Turnkey induction heating machine

Provide solution according to your requirement, well match with your production line

Related Products

100-300KW High Frequency Induction Heating Equipment

Power 30-300KW

Work Frequency 50-250Khz

This small power induction heater are high performance on small parts metal induction heating, easy to move and operate. Designed, produce and develpoment by Duolin team for 30 years, durable and good heating performance.

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, through heat generated in the object by eddy currents. An induction heater consists of induction power supply (induction heater) and inductor (coil) that is a shaped to contour the part, and a work station where the part is held and presented to the coil.

Quick Links

Tel.: +86 28 8393 0607

Mob.: +86 158 8242 2821

WhatsApp: +86 158 8242 2821

Add.: 112th Hancheng Road Xindu Industrial Zone Chengdu China